Order Online Chemraz O-Rings at O-RingSales | High Quality

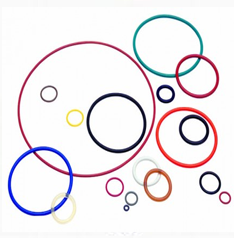

Fixing Rings are round formed mechanical gaskets which are

otherwise called O-rings, Packing Joints and Toric Joint. As the name

recommends, these rings are utilized for fixing fluid or gas in different

applications. These can be utilized in static applications just as unique

applications where there is relative movement between the parts and the Sealing

Ring. The rings are to a great extent utilized in pivoting siphon shafts and

pressure driven chamber cylinders because of their solid execution, basic

mounting prerequisites and financially savvy costs. HNBR O-Rings

Produced using diverse essential materials, These rings are

a circle of elastomer with a plate molded cross-area; these are intended to be

situated in a depression and compacted during get together between at least two

sections, making a seal at the interface. Fixing Rings are unbending in

structure and can withstand high temperature, weight and synthetic substances.

Accessible in different measurement and inch standard sizes,

are the most valuable fixing components at any point created. These are tough

and suitable for vacuum applications, high temperature applications and so

forth.

Fixing Rings are accessible in different materials, however

the most normally utilized materials incorporate diverse engineered rubbers and

elastomers. Different kinds of Sealing Rings accessible in the market; some of

them are EPDM, CR, NBR, HNBR and SIL.

Here in this article, purchasers can discover insights

concerning different sorts of Sealing Rings:

CR: These are impervious to sun beams, climate conditions

and ozone. The working temperature of these rings differs from-55-12 Celsius

degrees.

EPDM: Made from ethylene propylene terpolymer, these rings

are impervious to climate, ozone safe, water and synthetic concoctions.

Unseemly for Food Industry, these rings can be utilized in liquor, unified

fluids and in high-temperature fume condition. EPDM discover applications in

vehicle radiator, stopping mechanism and in clean shower gear. The working

temperature of these rings fluctuates from - 55 to 150 Celsius degrees.

HNBR: These rings are known for their erosion verification,

tear confirmation and misshapening evidence properties. The HNBR can likewise

withstand wear brought about by ozone, daylight and other climate conditions.

These are broadly utilized in clothes washers, car motors and refrigerating

frameworks. The working temperature of HNBR ranges from - 40 to 150 Celsius

degrees.

NBR: These are one of the most well known and sensible

fixing components accessible in the market. Produced using nitrile - butadiene elastic,

these can be utilized in pressure driven fluid, gas oil, water and silicon oil.

Not fitting for Polar Solvent, the working temperature of NBR shifts from - 40

to 120 Celsius degrees.

SIL: Made from premium quality silicon elastic, these are

known for their warmth obstruction, cold opposition and ozone obstruction. The

SIL fixing rings are broadly utilized in electric radiators, electric iron,

small scale wave stove, pot and drinking fountain.

Sher Bahadur has arranged this article about fixing ring

which are otherwise called O Rings and utilized for mechanical purposes. Visit

This Website=https://www.o-ringsales.com/

Article Source:

https://EzineArticles.com/master/Sher_Bahadur_Thapa/1104517

Article Source: http://EzineArticles.com/7123517

Comments

Post a Comment